The following is the updated instructions for the latest version of the Atirum Kit. If you purchased your Advent House Kit after 2022.07.01 then you will use these instructions to assemble the atrium.

Instructions for the assembly of the Atrium

Introduction:

The atrium comes in several

blocks of pre-cut parts. Each part will

need to be punched out of the block when it is needed. To be certain of no broken parts, we suggest using

an exacto knife to partially cut each of the tabs of each of the parts, front

and back while in their blocks. After

the part is punched out, use the exacto knife and some light sandpaper to clean

up each of the cut-out tab locations to be smooth.

The atrium goes together following

a numbering system. The atrium will

require gluing and we suggest using the same CA Glue (Super Glue) as used in

other parts of the kit. BUT DO NOT GLUE

until told to do so! We suggest you do

not punch out the parts from their blocks until each are needed per these

instructions. This helps avoid pieces

getting lost.

There are just a few “XTRA”

pieces, just in case something gets dropped, lost or broken. Be careful during punch out and during

assembly, and you hopefully won’t need any of those extra parts.

NOTE: All sub assemblies will have the etching

facing INTO the atrium. However, the 7

most visible pieces will also be covered with the Atrium Faces.

So let’s get started!

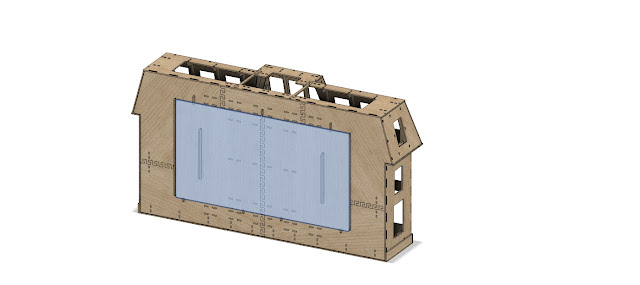

THE BACK Assembly:

-

Start with a good solid surface that you don’t

mind scratching up or getting glue on.

-

Start with parts 01 and 02 (the back pieces of

the atrium), laid down on the work surface with etching/numbers facing UP and interlock

their matching fingers. The ‘narrower’ part of the back will be the TOP of the

atrium.

-

Use braces 03 and 04 to hold the back pieces together. Press the braces parts 03 and 04 down into

the parts 01 and 02 in their noted slots.

-

** NOTE **

These braces WILL NOT go all the way through the back piece YET since

the tab system pushes THROUGH the back pieces and will extrude a tiny amount once

fully set in place. Once you have the

braces pushed down into the back piece as far as they will go, flip the assembly

over (so the etching is facing DOWN now) and press the two back pieces down and

over the tabs of braces 03 and 04.

-

Turn the assembly back etching face up and add

glue to those 8 tabs that went through parts 01 and 02, just to keep it stable. You’ll be able to add more glue later.

-

SET ASIDE to dry fully.

The Bottom Assembly:

-

Lay out parts 08 and 09, as well as part 08C,

with the etching FACE UP and interlock the small tabs at each point for

alignment.

-

The FRONT of the atrium will be the bump

out. The long straight edge will

eventually attach to the Back Assembly.

-

Use braces 10 and 11 on the front portion of

the bottom layout. Press the 2 braces

together and press down into the noted slots.

The double thickness of parts 10 and 11 together provide additional gluing

surface for the Atrium Faces in a later step.

Press the braces down firmly into the bottom assembly.

-

NOTE: Unlike with the Back Assembly, these braces

WILL sit flush to the bottom assembly parts as the tabs DO NOT push THROUGH the

flat bottom assembly.

-

Insert brace 12 on the back area of the bottom

assembly.

-

Add braces 29, 30, 31 and 32 in their noted

slots as well.

-

Add some glue to these braces to stabilize. We’ll add more glue later.

-

You’ll also want to add some glue between parts

10 and 11 and hold them together until they are set to make them a ‘single part’.

-

SET ASIDE to dry fully.

The TOP Assembly:

-

Lay out parts 05 and 06, as well as part 05C

with the etching FACE UP and interlock the alignment tabs.

-

Use brace 07 in the noted slots. Press firmly until fully seated on the Top

Assembly.

-

Add glue to this brace.

-

**** BE CAREFUL with this assembly for now

since it only has a single brace on it for now.

-

SET ASIDE to dry fully.

Back Braces:

-

Once the Back Assembly is fully dry, lay it

down again with etching FACE UP.

-

Add the small braces: Numbers 17-28 to each of

their noted slot locations. Ensure each

number aligns with its numbered slot.

-

*** NOTE: Just like the previous ‘back’ braces,

each brace will only press in part way.

Leave it that way for now.

-

Next add braces 13, 14, 15 and 16. ** STILL FROM THE ETCHED FACE SIDE ** Press the braces as far as they will go

through the Back Assembly.

-

Once each brace is in its correct spot and

pressed as far as it will go for now, carefully/gently lift the Back Assembly and

press each of the braces fully into the Back Assembly so that the brace tabs

protrude THROUGH the back assembly.

Ensure each of the braces are fully seated and flush with the etched

side of the back assembly.

-

Once you are sure ALL of the braces are in

their correct locations, as well as fully seated, add a small amount of glue to

each of the small braces to hold them in place.

You’ll be able to add more glue later.

-

Allow to dry fully.

BACK TO TOP Assembly:

-

Once the Back Assembly, with all of its braces,

are fully dry we can now start with final assembly of the Atrium Structure.

-

Lay the Top Assembly on the work surface with

the etching FACE UP, with the ‘bump out’ facing away from you.

-

Next, set the Back Assembly on the work surface

between you and the Top Assembly, with the etching FACE UP and with the

smaller/narrower edge (the top) facing AWAY from you.

-

Align the small braces on the Back Assembly, as

well as the zipper tabs across the top of the Back Assembly with the holes and

zipper tabs of the Top Assembly.

-

** MAKE NOTE ** there are 4 tabs on the top of

the Back Assembly that will not allow the Back Assembly zipper tabs to push

fully down into the zipper tabs on the Top Assembly until a future step. **

-

Now tip up the Back Assembly, set on end on top

of the Top Assembly zipper tabs, align each of the braces with their

slots/holes, and carefully press the tabs together in a ‘zipper’ motion,

working your way across the top of the Back Assembly.

-

Once many/most of the tabs are holding, gently

pick up the assembly and work the tabs fully into position so there is very

little light coming through the ‘zipper’.

Be gentle and it should hold pretty well for now.

-

** NO GLUE YET **

BACK/TOP TO Bottom Assembly:

-

Lay the Back/Top assembly on the work surface,

with the Back Assembly etching FACE UP and the Top Assembly vertical with the

Zipper tabs of the Back Assembly closer to you.

-

Lay the Bottom Assembly on the work surface between

you and the Back/Top Assembly with the etching FACE UP and the ‘bump out’ TOWARDS

you.

-

Align the zipper tabs along the long edge of

the Back and Bottom Assemblies.

-

** MAKE NOTE ** there are 4 tabs on the bottom of

the Back Assembly that will not allow the Back Assembly zipper tabs to push

fully down into the zipper tabs on the Bottom Assembly until a future step. **

-

Tip up the Back/Top Assembly and set on end on

top of the Bottom Assembly and carefully align the braces parts 16 and 17 with

the holes/slots available on the front side of the Bottom Assembly. These won’t hold tight but will help with

initial alignment. ** DO NOT GLUE THESE

YET **

-

While holding braces 16 and 17 in place with

the Bottom Assembly, align each of the tabs that are attached to the Back

Assembly with their matching slots/holes in the Bottom Assembly.

-

Now gently lift the whole assembly off the work

surface (the tabs won’t allow it to sit flush on the work surface anymore) and

CAREFULLY press the zipper tabs at the bottom of the Back Assembly down into

their matching zipper tabs on the back of the Bottom Assembly ALL WHILE aligning

each of the braces to slip into their respective locations.

-

*** NOTE – this process will take a little time

and patience. Be patient and gentle and

work your way across the zipper and braces, slowly working each tab and brace into

place. Ensure Parts 16 and 17 are

pressed into place as well.

-

Once you have the tabs and braces all aligned,

finish pressing the zipper tabs together very tightly so very little light can

get through the seam.

-

The assembly should be fairly stable but

continue to be gentle while handling.

-

Assuming all the tabs went in the right places

and all the zipper tabs aligned and are tight ….

-

NOW GLUE!

Add glue to all of the braces/slots/holes, as well as all of the zipper

tabs. Add glue from both sides of each

of the sub assembly connection points.

-

Continue to press the zipper seams together

(without gluing your fingers together or to the assembly).

-

Add additional glue to all tabs, inside and out

of the Bottom, Back and Top Assemblies.

-

** SET ASIDE and allow to dry fully before

moving to the next steps.

Final Structure Assembly:

-

After allowing the current structure to fully

dry, we can now add the final braces and do the final gluing.

-

Each of the vertical braces has a mirrored part,

as noted in the numbering system shown on the Bottom Assembly.

-

These angled braces will be the gluing surface

for the Atrium Faces in a future step.

-

Begin with parts 33 and 34. Align them with each other, then press the

bottom flange down into the noted location in the Bottom Assembly.

-

Then CAREFULLY lift the Top Assembly in that

location *JUST ENOUGH* to slip the top of the braces 33 and 34 into their

respective slot in the Top Assembly.

-

Carefully repeat this process with parts 35&36,

37&38 and 39&40.

-

** DO NOT GLUE YET **

-

** NOTE:

You DO have the option of gluing each of the pairs into their respective

locations prior to adding the next set of pairs, but if you do, please allow

the time needed to ensure the glue is fully dry on the current pair of vertical

braces before you try to gently lift the Top Assembly to slip the next pair

into their slots. Otherwise, you may

break loose that first gluing pair and then you’ll start creating something of

a mess with the ‘not-quite-dry’ glue.

-

** NOTE: These vertical braces can be a little finicky

(if not glued right away) and they may try to fall out of position with handling

of the structure. You may choose to use

a simple lightweight clamp to hold them, or maybe even tie a string around them

or use some simple scotch tape until you get the rest of the vertical braces

into place.

-

** NOTE:

You may choose to glue each of the vertical braces pairs to each other

prior to placing in the full assembly.

If you do this, BE SURE they are aligned perfectly while gluing them together.

-

Next, move over to parts 50&49, then

48&47, 46&45 and 44&43, placing each pair in their noted locations,

both on the Bottom Assembly as well as slipped up into the Top Assembly.

-

Once all of the pairs except 41&42 are in

place, NOW GLUE! You can now glue each

of these braces but be sure to hold the seams together tight for each one.

-

Lastly, once all of the other braces are in

place, tight and glued well, add the vertical braces parts 41&42 at the very

front center position, carefully slipping up into the Top Assembly.

-

GLUE WELL – while holding the seams tight.

Now go back and add any

additional glue you would like at this point.

Ensure each joint, tab, slot

etc has been glued well.

Set aside to fully dry.

** NOTE: Only the backside of

the Back Assembly will be visible on the finished model. All of the other areas

will be covered by the Atrium Faces. So

you may choose to paint that backside of the Back Assembly at this point.

You may also choose to add

some white/shiny paint to the inside of the Atrium structure to help with reflecting

the lighting as well. This step is

optional.

Atrium Faces:

-

While allowing the structure to fully dry, we’ll

now prep the Atrium Faces before they get assembled to the structure.

-

There are 10 Atrium Face pieces. Each needs to be punched out of their blocks,

lightly sanded and then painted on one side.

The following image shows how the faces should be laid out for painting.

Atrium

Faces Layout Image

-

Lay out all of the Atrium Face pieces as shown

in that image, then add paint.

-

** NOTE: You’ll want to ensure you get paint on

all of the edges as well since some of them will be visible on the finished

Atrium.

-

Once painted, allow to DRY FULLY.

-

Once the paint is fully dry, we then add Vellum

to the UNPAINTED side of the Atrium Face pieces.

-

Layout out all of the Atrium Face pieces PAINT

DOWN.

-

***** NOTE ****** DO NOT Cut out the ‘inside’ areas of the Atrium

Vellum pieces.

-

Cut out ONLY the outside perimeter of each of

the Vellum Atrium Faces with a little spare material all around.

-

Overlay the matching Vellum to the matching Atrium

Face pieces.

-

Once each of the Vellum pieces is aligned with

its correct Atrium face, carefully add a little CA Glue to the Atrium face. You

don’t need much.

-

*** NOTE – you want to keep the CA glue AWAY

from the inside openings so the CA glue doesn’t push out into those openings or

it will be visible on the finished Atrium.

-

*** NOTE – DO NOT SLIDE the vellum around when

placing on the Atrium faces. You DO NOT

want to get any CA glue inside of any of the opening areas.

-

Simply gently and carefully lay the vellum down

on top of the CA glue on the atrium faces.

-

Add a little pressure down on the vellum to

ensure it adheres well to the Atrium faces.

-

Repeat for all of the Atrium faces.

-

Allow to dry fully.

Once the vellum and Atrium faces are fully dry,

you will now come back and trim off the excess vellum from around the Atrium

Face pieces. Take about 1/8” off the

outside edges of each of the Atrium faces so you can’t see the vellum from the front

or sides of the faces..

The last Vellum cut is the oddly squareish

shape on the small rectangular Atrium face, as shown here:

Final Assembly:

-

And now we finally do full assembly of the Atrium

and finish it up.

-

** NOTE – You may want to do a dry ‘fit up’ on

all these faces before adding glue. Take

the time to ensure each one is in the right place and fits as expected.

-

** NOTE – when gluing these faces in – DO NOT

allow the glue to get out into the open window areas or the glue will be

visible on the finished Atrium

-

** NOTE – Add glue to the vertical braces and across

the bottom first. Then, once assembled,

you can come back and add additional glue across the inside edge of the tops of

each of the angled faces.

-

Start with the 2 larger rectangular faces and

place on top of the Atrium, with the vellum FACE IN/DOWN to the structure. The 4 tabs across the back of the Back

Assembly will assist in aligning those 2 pieces correctly.

-

** DO NOT GLUE YET **

-

Next add the smaller rectangle piece between

the 2 larger ones. Again, use the 2 tabs

on the backside for alignment. Once all

3 pieces are perfectly aligned and centered on the top of the atrium. Carefully glue into place.

-

** NOTE - DO NOT allow glue to get out into the

open window areas or it will be visible when finished. It doesn’t take much CA glue, just enough to

get it to hold.

-

Next add the 2 smaller side faces, as shown

below, to each far end of the structure.

-

Use the 2 slots on each of the Atrium Faces and

align with the 2 tabs on the side edge of the Back Assembly to align these 2

parts.

-

**NOTE – Ensure the Vellum is facing IN!

-

**NOTE – Some light trimming may be required on

the top (the short edge) of these faces to fit underneath the top faces.

-

Next you add the 2 long parallelogram faces to

the long front faces.

-

With the Vellum FACE IN – slip the face up

under the top faces and align with the 2 shorter side faces.

-

**NOTE – due to the angles, there WILL be small

gaps at these connection points.

-

And then the 2 tiny parallelogram faces go on

the sides of the bump outs. (see below)

-

And lastly, the front center face goes on.

AND THAT’S IT! The Atrium is now complete and ready for

display. Once the Tower is complete, you’ll

set it down into that one small square area you cut out of the center of the

top of the Atrium.