These following steps show you how to assemble the new Atrium

KIT BLOCKS:

Like many other parts, the Atrium is contained in pre-cut kit blocks. We suggest you keep the parts in their blocks until you need them.

CUT OUT PARTS:

INITIAL PARTS LAYOUT:

Once the parts are removed from the block, begin layout as shown above. The 2 back parts are in the middle, the larger frame Portion (the bottom) is at the bottom of the picture, and the smaller frame part (the top) is at the top of the picture.

Begin by laying out where each of the bracing and tabs belong, as shown in the picture. Align the different small brace tabs with their matching hole patterns.

The cross braces down the middle of each of the larger pieces are designed to fit in only one way. The straight pieces will be glued next to the tabbed braces to add additional gluing support.

PLACE THE BRACES:

After ensuring each of

the braces are where they belong, we glue them into the back piece. Also add the several cross

braces down the middle of the top and bottom frame pieces. Also note the 4 tiny braces (only 2 are shown in the image above) that will go on the outer most front corners of the bottom piece. These pieces will help support the side Atrium Faces.

Also, the larger center

brace should be carefully glued together before

gluing into its aligned slots on the bottom frame. (make sure they are

perfectly aligned when you glue them together!)

TIP UP THE BOTTOM FRAME

Once you have test fitted the bottom piece to the back piece (the picture above has it laying on its back), you can then add glue and apply pressure for a sure gluing hold.

With the braces glued in place, you can now tip

up the bottom frame and slip into the aligned slots and holes. Do this test fit before gluing. Note the braces that push through the bottom

of the bottom piece. These longer tabs

will be used to help hold the atrium in place once placed on the top of the

Advent House.

Once you have test fitted the bottom piece to the back piece (the picture above has it laying on its back), you can then add glue and apply pressure for a sure gluing hold.

TIP UP THE TOP FRAME:

In the exact same manner as we did with the

bottom piece, we tip up the top piece (in the picture, the Atrium is still

laying on its back). Align the holes and

slots/tabs and test fit. Assuming it

fits perfectly, feel free to glue it up.

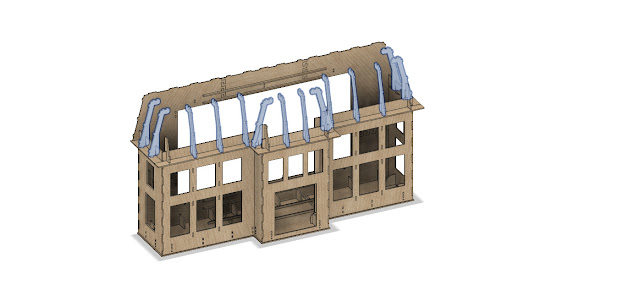

ADD VERTICAL BRACING:

Once the glue is dried, you now trim the excess vellum away from the parts. The easiest way we have found is to lay the part vellum-down on a hard surface (that you don’t mind having get cut). Then use the very tip of a very sharp exacto knife and just run it around the edges. Should clean up really nice. Take your time to clean these up.

All of the vertical bracing will need to be

glued in sets. Take 2 of the braces, match them up and glue them. Make note – you MUST have these well aligned

when gluing them up in pairs!

There will be 9 total vertical braces once they

are glued up. After allowing the glue to dry/cure, you'll then want to sand the long face (where the Atrium Faces will attach). You'll want that long face pretty flat to gain as much glueing surface as possible. We use a tabletop belt sander and just place them on the sander for 2 or 3 seconds, just to clear away any irregular surface areas.

You can see that all of the vertical bracing is

in. Once you are sure everything fits

correctly, feel free to glue.

Once you have all the

parts where they belong and it looks awesome – Go to town with the glue. Make sure you hit all the edges and

connections/seams, then allow to dry fully.

PAINT ALL THE PARTS:

The structure doesn’t require paint on the

inside or the front, but I like to add some just to clean it up a little. Be sure to give a good painting to the

backside of the Atrium because it will be the most visible portion of the

structure.

The Atrium Faces only need to be painted on one

side. Ensure you have them all laid out

with as shown above so that you are sure to paint the correct side. You can use double sided tape to hold these faces to the plastic on the tables. (Spray cans can sometimes push those pieces around on the table) Also, you’ll want to be sure you get some

paint on the edges of each of the faces since some of those edges will be visible

once assembled.

ADD VELLUM: (Minor Vellum Change: 2019.12.06 - Does not affect assembly)

We provide printed vellum so you can easily see where each part is to go.

*** PLEASE NOTE: *** Regarding gluing the Atrium Faces: You want to be careful to keep the glue away from the open 'window' portions of the Atrium faces. You don't want glue pushing out into those window areas.

Add a small

amount of CA glue to the backs of the Atrium Faces, then place gently down on

the vellum, aligning with the pre-printed marks on the vellum.

Once you place the part on the vellum – DO NOT

MOVE IT – or it will leave streaks in the ‘windows’ areas.

Be sure to have plenty of glue on the

outside corners of each face, though – as this will prevent the corners from

trying to lift later on. Any glue that

pushes outside of the faces isn’t a problem since we’ll be trimming off the

excess vellum around the faces.Once the glue is dried, you now trim the excess vellum away from the parts. The easiest way we have found is to lay the part vellum-down on a hard surface (that you don’t mind having get cut). Then use the very tip of a very sharp exacto knife and just run it around the edges. Should clean up really nice. Take your time to clean these up.

Make note that on the center top piece (the narrower piece with 2 holes), you need to remove the vellum from the SQUARE hole and LEAVE the vellum in the ROUNDED CORNERS hole (as seen below)

If you have purchased our lighting kit, or if you want to add LED strip lighting to your model, we have found the layout shown above works very well.

ASSEMBLE THE FACES: (Minor Change: 2019.12.06 - We now include 'Tabs' as part of the structure to assist in the assembly of the faces.)

Start with the faces on the top. Align the 3 top faces as shown in this image and center the 3 of them together with the outside edges of the atrium structure. The structure tabs (not shown in these images) on the backside will help align the Atrium Faces where they belong.

Start with the faces on the top. Align the 3 top faces as shown in this image and center the 3 of them together with the outside edges of the atrium structure. The structure tabs (not shown in these images) on the backside will help align the Atrium Faces where they belong.

Once you have the 3 top parts fitting correctly (using the Structure tabs to help align), you'll then add glue to the structure and carefully place the Atrium faces onto the structure.

Reminder: You don't want glue pushing out into the Window areas, so make note of where you place the glue on the structure.

Moving on to the side faces, dryfit the side Atrium Face, using the top back corner tab(not shown in image above) as an aligning reference. Then run a bead of glue

up under the top face, and down both the structure, and the

vertical brace, as well as on the small corner brace (not shown in image above). You may want to run 2 strips of glue up

the vertical brace for the extra holding power.

Reminder: Once you place the Atrium face, you do not want to move it! So take your time to set it in place correctly.

Repeat this process on the other side Atrium Face, then do the 2 front large side pieces in the same manner.

Then add the two small side pieces, and finally the front piece.

COMPLETE!

LIGHTING OPTION:

And it’s complete! The atrium is now ready for display. You can go ahead and add extra glue from the

inside if you like, just be sure to not get any glue in the open window areas! Once you have the Tower finished it will sit

inside the centered square hole on top.

If you have purchased our lighting kit, or if you want to add LED strip lighting to your model, we have found the layout shown above works very well.

Questions? Please feel free to contact us on our website or our etsy store!